Material Safety Data Sheet Oxygen Gas

1. PRODUCT AND COMPANY IDENTIFICATION

Product name : Oxygen

Chemical formula : O2

Synonyms : Oxygen, Oxygen gas, Gaseous Oxygen, GOX

Product Use Description: General Industrial

Company : TIEN PHAT INDUSTRIAL GASCO. LTD

Address : 322/17 Huynh Van Luy Street, Phu Loi Ward,

Thu Dau Mot City, Binh Duong Province, Vietnam.

Telephone : +84 650 381 9801

2. COMPOSITION/INFORMATION ON INGREDIENTS

| Components | CAS Number | Concentration (Volume) |

| Oxygen | 7782-44-7 | 100 % |

Concentration is nominal. For the exact product composition, please refer to Tien Phat technical specification.

Material Safety Data Sheet Oxygen

3. HAZARDS IDENTIFICATION

Emergency Overview

High pressure, oxidizing gas.

Vigorously accelerates combustion.

Keep oil, grease, and combustibles away.

May react violently with combustible materials.

Potential Health Effects

Inhalation: Breathing 75% or more oxygen at atmospheric pressure for more than a few hours may cause nasal stuffiness, cough, sore throat, chest pain and breathing difficulty. Breathing pure oxygen under pressure may cause lung damage and also central nervous system effects.

Eye contact: No adverse effect.

Skin contact: No adverse effect.

Ingestion: Ingestion is not considered a potential route of exposure.

Exposure Guidelines

Primary Routes of Entry: Inhalation

Target Organs: None known.

Aggravated Medical Condition

If oxygen is administered to persons with chronic obstructive pulmonary disease, raising the oxygen concentration in the blood depresses their breathing and raises their retained carbon dioxide to a dangerous level.

4. FIRST AID MEASURES

General advice: Remove victim to uncontaminated area wearing self contained breathing apparatus. Keep victim warm and rested. Call a doctor. Apply artificial respiration if breathing stopped.

Eye contact: Seek medical advice.

Skin contact: Wash with water and soap as a precaution.

Ingestion: Ingestion is not considered a potential route of exposure.

Inhalation: Consult a physician after significant exposure. Move to fresh air. If breathing has stopped or is labored, give assisted respirations. Supplemental oxygen may be indicated. If the heart has stopped, trained personnel should begin cardiopulmonary resuscitation immediately.

5. FIRE- FIGHTING MEASURES

Suitable extinguishing media: All known extinguishing media can be used.

Specific hazards: Most cylinders are designed to vent contents when exposed to elevated temperatures.

Further information: Some materials that are noncombustible in air will burn in the presence of an oxygen enriched atmosphere (greater than 23%). Fire resistant clothing may burn and offer no protection in oxygen rich atmospheres.

6. ACCIDENTAL RELEASE MEASURES

Personal precaution: Clothing exposed to high concentrations may retain oxygen 30 minutes or longer and become a potential fire hazard. Stay away from ignition sources. Evacuate personnel to safe areas. Wear self-contained breathing apparatus when entering area unless atmosphere is proved to be safe. Ventilate the area.

Environmental precautions: Do not discharge into any place where its accumulation could be dangerous. Prevent further leakage or spillage if safe to do so.

Methods for cleaning up: Ventilate the area.

Additional advice : If possible, stop flow of product. Increase ventilation to the release area and monitor concentrations. If leak is from cylinder or cylinder valve, call the Cryotech Vietnam emergency telephone number. If the leak is in the user's system, close the cylinder valve, safely vent the pressure, and purge with an inert gas before attempting repairs.

7. HANDLING AND STORAGE

Handling

All gauges, valves, regulators, piping and equipment to be used in oxygen service must be cleaned for oxygen service. Oxygen is not to be used as a substitute for compressed air. Never use an oxygen jet for cleaning purposes of any sort, especially clothing, as it increases the likelihood of an engulfing fire. Only experienced and properly instructed persons should handle compressed gases. Protect cylinders from physical damage; do not drag, roll, slide or drop. Do not allow storage area temperature to exceed 50°C (122°F). Before using the product, determine its identity by reading the label. Know and understand the properties and hazards of the product before use. When doubt exists as to the correct handling procedure for a particular gas, contact the supplier. Do not remove or deface labels provided by the supplier for the identification of the cylinder contents.

When moving cylinders, even for short distances, use a cart (trolley, hand truck, etc.) designed to transport cylinders. Leave valve protection caps in place until the container has been secured against either a wall or bench or placed in a container stand and is ready for use. Use an adjustable strap wrench to remove over-tight or rusted caps. Before connecting the container, check the complete gas system for suitability, particularly for pressure rating and materials. Before connecting the container for use, ensure that back feed from the system into the container is prevented. Ensure the complete gas system is compatible for pressure rating and materials of construction. Ensure the complete gas system has been checked for leaks before use. Employ suitable pressure regulating devices on all containers when the gas is being emitted to systems with lower pressure rating than that of the container. Never insert an object (e.g. wrench, screwdriver, pry bar, etc.) into valve cap openings. Doing so may damage valve, causing a leak to occur. If user experiences any difficulty operating cylinder valve discontinue use and contact supplier. Close container valve after each use and when empty, even if still connected to equipment. Never attempt to repair or modify container valves or safety relief devices. Damaged valves should be reported immediately to the supplier. Do not use containers as rollers or supports or for any other purpose than to contain the gas as supplied. Never strike an arc on a compressed gas cylinder or make a cylinder a part of an electrical circuit. Do not smoke while handling product or cylinders. Never re-compress a gas or a gas mixture without first consulting the supplier. Never attempt to transfer gases from one cylinder/container to another. Always use backflow protective device in piping. When returning cylinder install valve outlet cap or plug leak tight. Never permit oil, grease, or other readily combustible substances to come into contact with valves or containers containing oxygen or other oxidants. Do not use rapidly opening valves (e.g. ball valves). Open valve slowly to avoid pressure shock. Never pressurize the entire system at once. Use only with equipment cleaned for oxygen service and rated for cylinder pressure. Never use direct flame or electrical heating devices to raise the pressure of a container. Containers should not be subjected to temperatures above 50°C (122°F). Prolonged periods of cold temperature below -30°C (-20°F) should be avoided.

Storage

Containers should be stored in a purpose build compound which should be well ventilated, preferably in the open air. Full containers should be stored so that oldest stock is used first. Stored containers should be periodically checked for general condition and leakage. Observe all regulations and local requirements regarding storage of containers. Protect containers stored in the open against rusting and extremes of weather. Containers should not be stored in conditions likely to encourage corrosion. Containers should be stored in the vertical position and properly secured to prevent toppling. The container valves should be tightly closed and where appropriate valve outlets should be capped or plugged. Container valve guards or caps should be in place. Keep containers tightly closed in a cool, well-ventilated place. Store containers in location free from fire risk and away from sources of heat and ignition. Full and empty cylinders should be segregated. Do not allow storage temperature to exceed 50°C (122°F). Display "No Smoking or Open Flames" signs in the storage areas. Return empty containers in a timely manner. Flammable storage areas should be separated from oxygen and other oxidizers by a minimum distance of 20 ft. (6.1 m.) or by a barrier of non-combustible material at least 5 ft. (1.5 m.) high, having a fire resistance rating of at least 1/2 hour.

Technical measures/Precautions

Containers should be segregated in the storage area according to the various categories (e.g. flammable, toxic, etc.) and in accordance with local regulations.

8. EXPOSURE CONTROLS / PERSONAL PROTECTION

Personal protective equipment

Respiratory protection: Users of breathing apparatus must be trained.

Hand protection: Sturdy work gloves are recommended for handling cylinders. The breakthrough time of the selected glove(s) must be greater than the intended use period.

Eye protection: Safety glasses recommended when handling cylinders.

Skin and body protection: Safety shoes are recommended when handling cylinders.

Special instructions for: Ensure adequate ventilation, especially in confined areas. Gloves must be protection and hygiene clean and free of oil and grease.

9. PHYSICAL AND CHEMICAL PROPERTIES

Form : Compressed gas.

Color : Colorless gas

Odor : No odor warning properties.

Molecular Weight : 32 g/mol

Relative vapor density : 1.1 (air = 1)

Relative density : 1.1 (water = 1)

Density : 0.081 lb/ft3 (0.0013 g/cm3) at 70 °F (21 °C)

Note : (as vapor)

Specific Volume: 12.08 ft3/lb (0.7540 m3/kg) at 70 °F (21 °C)

Boiling point/range: -297 °F (-183 °C)

Critical temperature : -180 °F (-118 °C)

Melting point/range : -362 °F (-219 °C)

Water solubility : 0.039 g/l

10. STABILITY AND REACTIVITY

Stability : Stable under normal conditions.

Materials to avoid : Flammable materials.

Organic materials.

Avoid oil, grease and all other combustible materials.

11. TOXICOLOGICAL INFORMATION

Acute Health Hazard

Ingestion : No data is available on the product itself.

Inhalation : No data is available on the product itself.

Skin : No data is available on the product itself.

Chronic Health Hazard

Premature infants exposed to high oxygen concentrations may suffer delayed retinal damage that can progress to retinal detachment and blindness. Retinal damage may also occur in adults exposed to 100% oxygen for extended periods (24 to 48 hr). At two or more atmospheres central nervous system (CNS) toxicity occurs. Symptoms include nausea, vomiting, dizziness or vertigo, muscle twitching, vision changes and loss of consciousness and generalized seizures. At three atmospheres, CNS toxicity occurs in less than two hours and at six atmospheres in only a few minutes.

12. ECOLOGICAL INFORMATION

Ecotoxicity effects

Aquatic toxicity : No data is available on the product itself.

Toxicity to other organisms: No data available.

Persistence and degradability

Mobility : No data available.

Bioaccumulation : No data is available on the product itself.

Further information

No ecological damage caused by this product.

13. DISPOSAL CONSIDERATIONS

Waste from residues / unused: Return unused product in orginal cylinder to supplier.

Contact supplier if products guidance is required.

Contaminated packaging: Return cylinder to supplier.

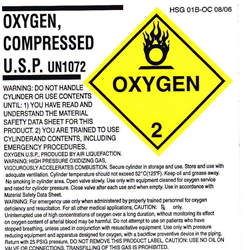

14. TRANSPORT INFORMATION

CFR

Proper shipping name : Oxygen, compressed

Class : 2.2 (5.1)

UN/ID No. : UN1072

IATA

Proper shipping name : Oxygen, compressed

Class : 2.2 (5.1)

UN/ID No. : UN1072

IMDG

Proper shipping name : OXYGEN, COMPRESSED

Class : 2.2 (5.1)

UN/ID No. : UN1072

CTC

Proper shipping name : OXYGEN, COMPRESSED

Class : 2.2 (5.1)

UN/ID No. : UN1072

Further Information

Avoid transport on vehicles where the load space is not separated from the driver's compartment. Ensure vehicle driver is aware of the potential hazards of the load and knows what to do in the event of an accident or an emergency.

15. REGULATORY INFORMATION

OSHA Hazard Communication Standard (29 CFR 1910.1200) Hazard Class(es) Oxidizer. Compressed Gas.

This product does not contain any chemicals known to cause cancer, birth defects or any other harm.

16. OTHER INFORMATION

NFPA Rating

Health : 0

Fire : 0

Instability : 0

Special : OX

HMIS Rating

Health : 0

Flammability : 0

Physical hazard : 3

Material Safety Data Sheet Oxygen

Sản phẩm khác